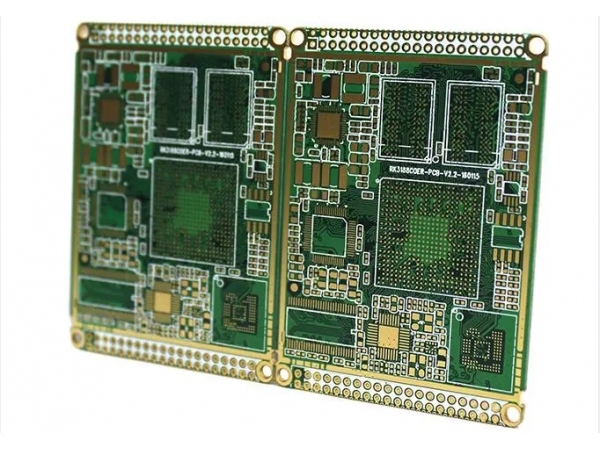

Before PCB proofing, customers need to provide a series of relevant documents to ensure the accuracy and efficiency of the manufacturing process. These files are the basis of PCB manufacturing, and they contain detailed information about board design, component packaging, layer structure, and more. This article will detail the documents required for PCB proofing and their importance.

PCB design document

The PCB design file is one of the most basic files and is usually submitted in the Gerber file format. The Gerber file contains information about each layer of the circuit board, such as wires, pads, holes, etc. In addition, the design document should also include the relevant DRC(Design Rule Check) document to ensure that the board design meets the manufacturing requirements.

Component package library file

The component package library file contains package information for all components on the board, such as package size, pin spacing, and so on. These files are usually submitted in CAD format or other supported formats. When providing package library files, make sure that all components used have appropriate packages to avoid problems during manufacturing.

Silk-screen document

A screen file is a file used to make text, identifiers, and patterns on a circuit board. This information facilitates identification during board manufacturing and assembly. Silk screen files are usually submitted in PDF or DXF format and need to contain the correct font, size and location information.

Drilling file

The drill file contains information about the location and dimensions of all the holes that need to be drilled on the board. This information is critical to the fabrication and assembly of the board because it determines how the component pins are connected to the board wires. The borehole file is usually submitted in Excel or CSV format, and ensure that the correct hole coordinates and aperture data are included in the file.

Test point file

Test point files are used to identify test point locations on the board for testing and debugging during manufacturing and assembly. The test point should be easily accessible on the board, and when submitting the test point file, make sure that the file contains the correct test point location and identification information.

Bill of Materials (BOM) file

The Bill of Materials (BOM) file contains the details of all the components on the circuit board, such as model, specifications, suppliers, etc. This information is critical to sourcing components and ensuring the accuracy of board assembly. When submitting the BOM file, ensure that the file contains complete component information and is formatted according to the manufacturer's requirements.

Assembly drawings and process requirements documents

Assembly drawings and process requirements documents provide detailed guidance on board assembly, including assembly sequence, welding requirements, cleaning treatments, and more. These documents are essential to ensure the quality and performance of the board and should be prepared and submitted in accordance with the manufacturer's requirements.

In order to ensure the accuracy and efficiency of PCB proofing, customers need to provide a series of relevant documents, including PCB design documents, component package library documents, screen printing documents, drilling documents, test point documents, bill of materials (BOM) documents and assembly drawings and process requirements documents.

When preparing these documents, be sure to follow the manufacturer's requirements and format specifications to ensure the accuracy and compatibility of the documents. By providing complete documentation and information, customers can establish good communication and cooperation with PCB manufacturers, so as to achieve high-quality circuit board manufacturing and assembly services.