In the field of modern industry and automation, the Android industrial control board has become a key technical component, which provides a more intelligent and flexible solution for various industrial control applications. This article will explore how to select and use Android industrial motherboards to meet the needs of different industries.

1. Understand the needs: Before choosing the Android industrial motherboard, first of all, you must clarify your specific needs. Different industrial applications may require different specifications of motherboards, so a clear purpose is crucial to choosing the right model.

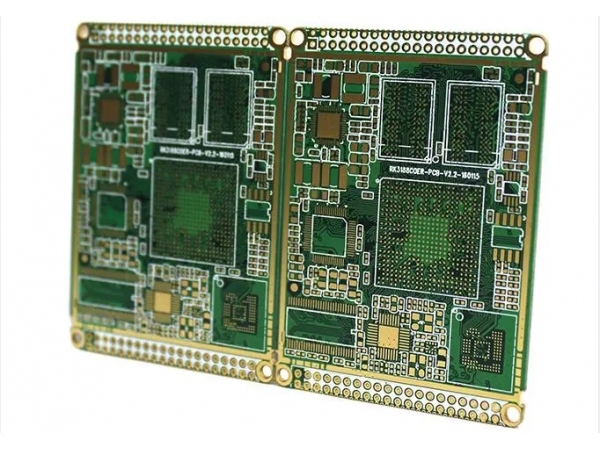

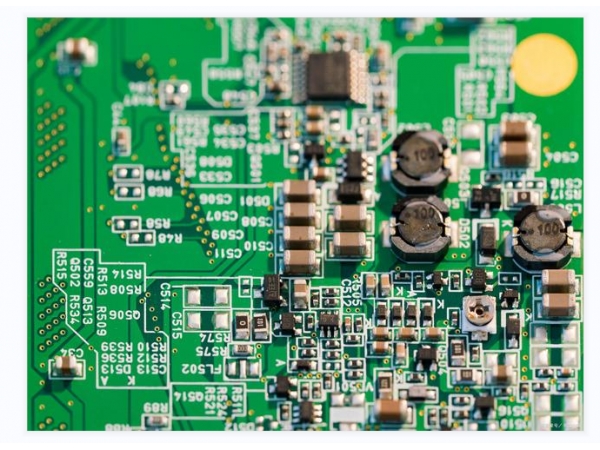

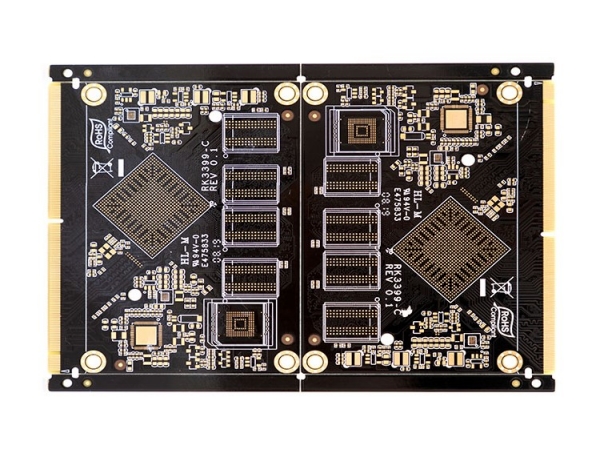

2. Determine performance requirements: Considering the complexity of industrial control applications, performance is an important indicator. The processing power, memory capacity and graphics performance of the Android industrial motherboard should be selected according to the requirements of the application.

3. Confirm the interface and scalability: Different applications may require different types of interfaces, such as USB, HDMI, RS-232, etc. Make sure the board you choose has enough interfaces to support your device connectivity needs.

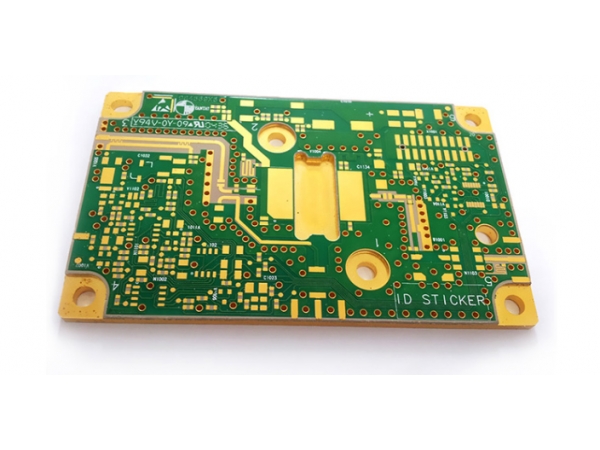

4. Consider the working environment: the industrial control board usually needs to operate in a harsh working environment, such as high temperature, low temperature, high humidity, etc. Therefore, it is crucial to choose a motherboard with a good operating temperature range and durability.

5. Software compatibility: Ensure that the selected Android industrial control board is compatible with the industrial control software and operating system you need. This helps simplify deployment and maintenance.

6. Safety: The safety of the industrial control system is crucial. Choose a motherboard with security features such as trusted startup, remote management, and data encryption to protect your system from potential threats.

7. System integration: Once the appropriate Android industrial motherboard is selected, ensure that it is effectively integrated with other hardware components and devices. This requires precise hardware connectivity and software configuration.

8. Testing and maintenance: Before the actual use, the system is tested and verified to ensure that everything runs properly. At the same time, establish regular maintenance procedures to ensure the stability and reliability of the system.

Selecting and using Android industrial control boards requires careful consideration of various factors to meet your industrial control application needs. Choosing the right motherboard will give you greater flexibility and intelligence for your industrial automation applications, helping to improve productivity and quality.