Communication motherboard SMT chip processing is an indispensable part of modern electronics manufacturing industry. By attaching components precisely to the printed circuit board, circuit connection and signal transmission are realized. This paper will thoroughly analyze the characteristics of SMT processing of communication motherboard from many aspects and reveal its secrets.

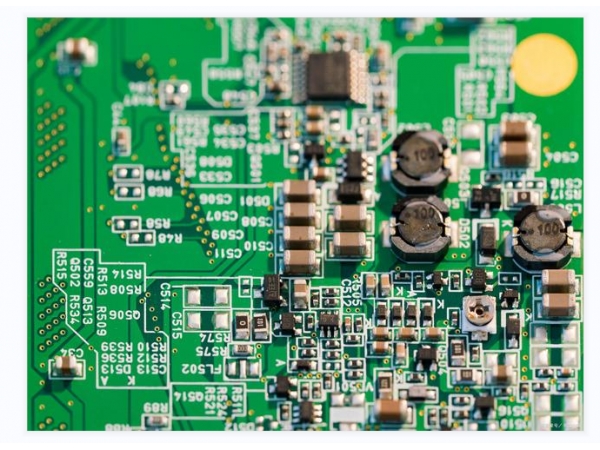

01. Communication motherboard SMT chip processing with a high degree of accuracy. This processing method is carried out by automated equipment, which can achieve high-precision component positioning and welding, ensuring the quality and stability of the circuit board. Compared with manual SMT, SMT SMT processing has higher reliability and lower failure rate, thereby improving the overall production efficiency.

02. Communication motherboard SMT chip processing has high efficiency. Due to the use of automation equipment, SMT chip processing can quickly and continuously complete the task of mounting components, greatly shortening the production cycle. At the same time, SMT technology also supports multi-station simultaneous operation, improving production efficiency and capacity.

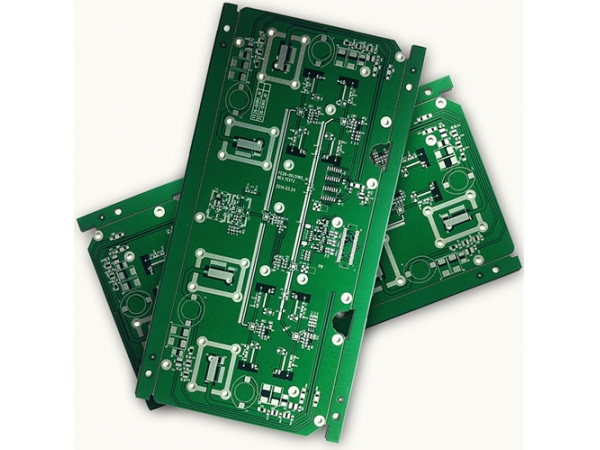

03. Communication motherboard SMT chip processing has a low cost. Compared with the traditional manual chip processing, SMT chip processing reduces manpower input and reduces production costs. The use of automation equipment can also reduce personnel training costs and losses caused by operational errors. Therefore, communication motherboard SMT chip processing is an effective way to improve manufacturing competitiveness and reduce production costs.

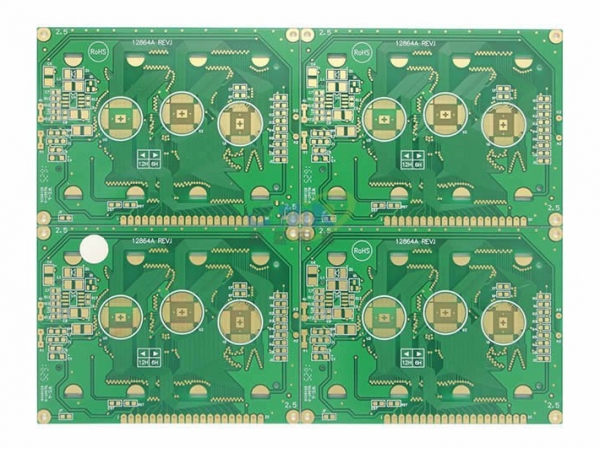

04.Communication motherboard SMT SMT processing has good adaptability. Whether it is small batch production or large-scale production, SMT patch processing can meet the needs. Moreover, SMT chip technology has a good adaptability for various models and sizes of components, which is suitable for different types of communication motherboard manufacturing.

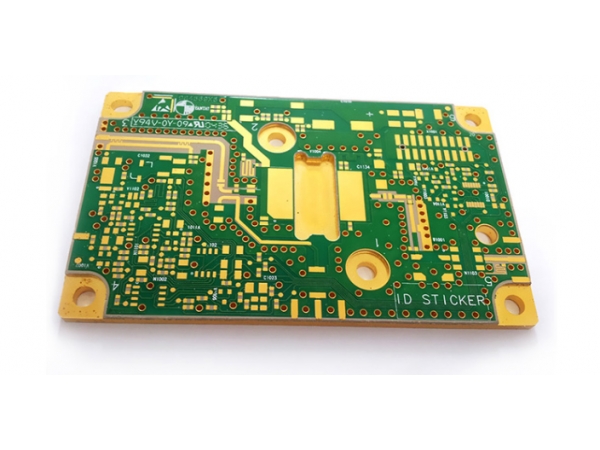

05. Communication motherboard SMT chip processing has high maintainability. Due to the use of automation equipment, SMT chip processing can track and monitor various indicators in the production process, and find and solve problems in time. At the same time, the modular design of the automation equipment makes maintenance and replacement easier and faster, reducing downtime and repair costs.

To sum up, SMT processing of communication motherboard has become an indispensable technology in the field of modern electronics manufacturing with its high accuracy, high efficiency, low cost, good adaptability and maintainability. Through in-depth understanding of its characteristics, we can better apply and play the advantages of this processing method to achieve production efficiency and quality assurance.