In the field of electronics manufacturing, PCBA processing is a complex and delicate process involving multiple links and steps. Among them, DIP plug-in, as an important part of PCBA processing, has a crucial impact on product quality and production efficiency. This article will focus on the PCBA processing process, DIP plug-in link need to pay attention to several aspects.

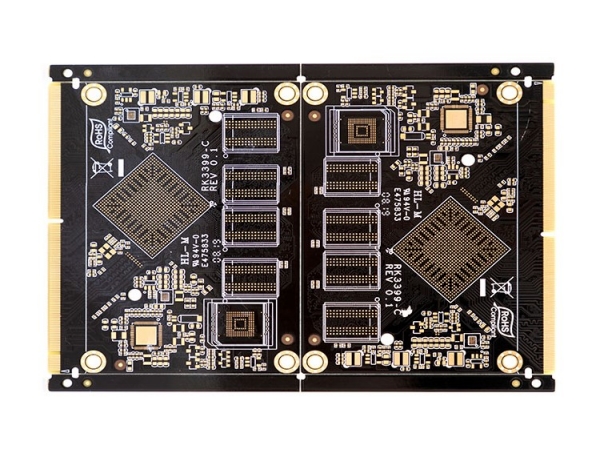

Component selection and inspection

Before processing the DIP plug-in, it is first necessary to select the appropriate electronic components. The selection of components should be based on the circuit design and product performance requirements, while ensuring that they have good stability and reliability. For selected components, it is also necessary to carry out strict warehousing inspection, including appearance inspection, electrical performance testing, etc., to ensure that the quality of components meets the production requirements.

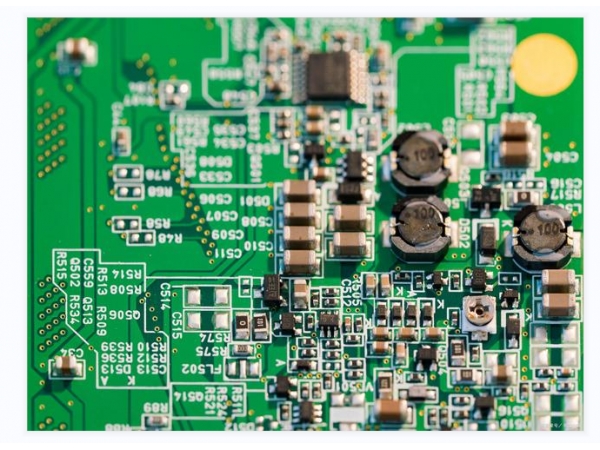

Plug-in process and operation specification

During the DIP plug-in process, it is essential to follow the correct plug-in process and operating specifications. The operator should be familiar with the use method and operating procedures of the insert machine to ensure that the components are accurately inserted into the corresponding position of the PCB board. In addition, pay attention to the plug-in order and plug-in direction to avoid inserting wrong or reverse components. For special components or complex circuits, specific plug-in tools or auxiliary devices may be required to improve plug-in accuracy and efficiency.

Electrostatic protection measures

Static electricity can be a potential threat to electronic components, so electrostatic protection is an essential measure during the processing of DIP plug-ins. The operator must wear an ESD bracelet, wear ESD clothes, and ensure that the working area is equipped with ESD facilities. At the same time, the insertion machine is regularly tested and adjusted to ensure that it is in a good anti-static state.

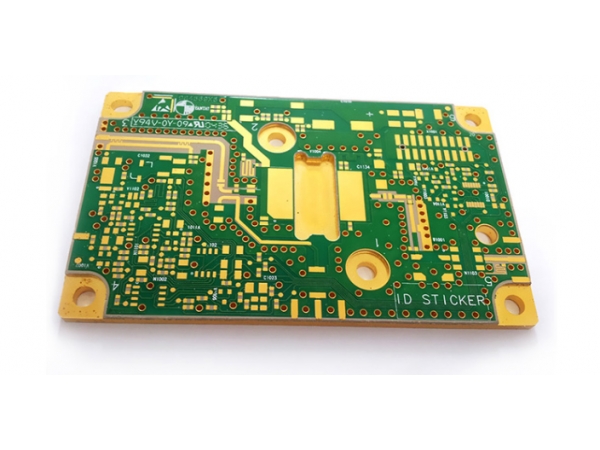

Production environment and equipment maintenance

DIP plug-in processing has higher requirements for the production environment, and it is necessary to maintain constant temperature and humidity, dust-free and pollution-free environmental conditions. In addition, regular maintenance and maintenance of production equipment such as insert machines can ensure its stable operation and plug-in accuracy. When the equipment fails or is abnormal, it should be stopped in time for inspection and repair to avoid production delays and quality problems caused by equipment problems.

Quality inspection and testing

After the DIP plug-in is completed, rigorous quality checks and tests are essential. Quality inspection shall include appearance inspection, connectivity test, electrical performance test, etc., to ensure that all components are correctly inserted and free from damage. For unqualified products, they should be reworked or scrapped in time to avoid flowing into the next process. At the same time, establish a sound quality traceability system to track and analyze quality problems in the production process in order to continuously improve and optimize the production process.

Personnel training and team building

Improving the quality and efficiency of DIP plug-in processing is inseparable from professional operators and collaborative teams. Enterprises should regularly organize personnel training to improve the skill level and quality awareness of operators. At the same time, strengthen team building and management, promote communication and collaboration among team members, and form a good working atmosphere and corporate culture.

Safety in production and environmental awareness

In the DIP plug-in processing process, safety production and environmental awareness can not be ignored. Enterprises should establish a sound production safety management system and emergency plans to ensure that the production process is safe and controllable. At the same time, we actively promote the concept of green manufacturing and environmental protection, reduce waste emissions and resource consumption, and contribute to the sustainable development of enterprises.

The DIP plug-in link in PCBA processing needs to pay attention to the selection and inspection of components, plug-in technology and operation specifications, electrostatic protection measures, production environment and equipment maintenance, quality inspection and testing, personnel training and team building, and safety production and environmental awareness. Only in these aspects to achieve strict control and continuous improvement, in order to ensure the high quality and efficiency of DIP plug-in processing, laying a solid foundation for the steady development of enterprises.